Pneumatic Blender

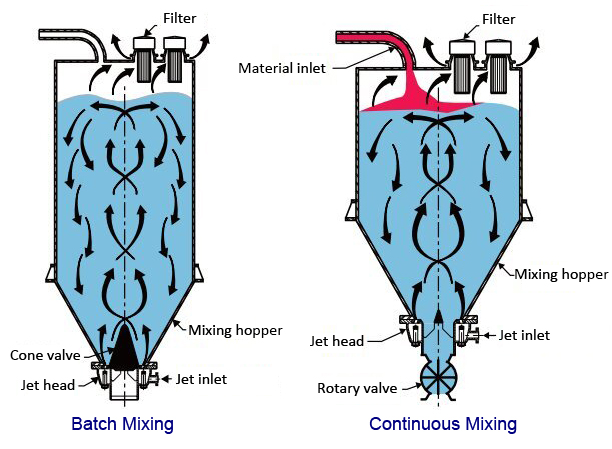

The pneumatic blender utilizes compressed air as a power source. Compressed air enters the mixing chamber through the nozzles on the special head. As the introduced compressed air expands back to atmospheric pressure, it creates a forceful and high-speed turbulent mixing action. This process causes the materials to form a fluidized mixing state within the mixing hopper.

The pneumatic blender is suitable for mixing large batches of materials with different bulk densities and fineness. It is ideal for situations requiring homogeneity and fast, high-capacity mixing.

How it works

- Materials enter and fill the mixing hopper to the preset level through a rotary valve or screw feeder.

- Compressed air is released from the nozzle in a pulsed cycle. The compressed air drives the material in a fluidized state and mixes it quickly and evenly.

- After mixing, the air is filtered and vented into the atmosphere or recycled for reuse.

- Once the mixing is complete, the bottom cone valve is opened to discharge the mixed product.