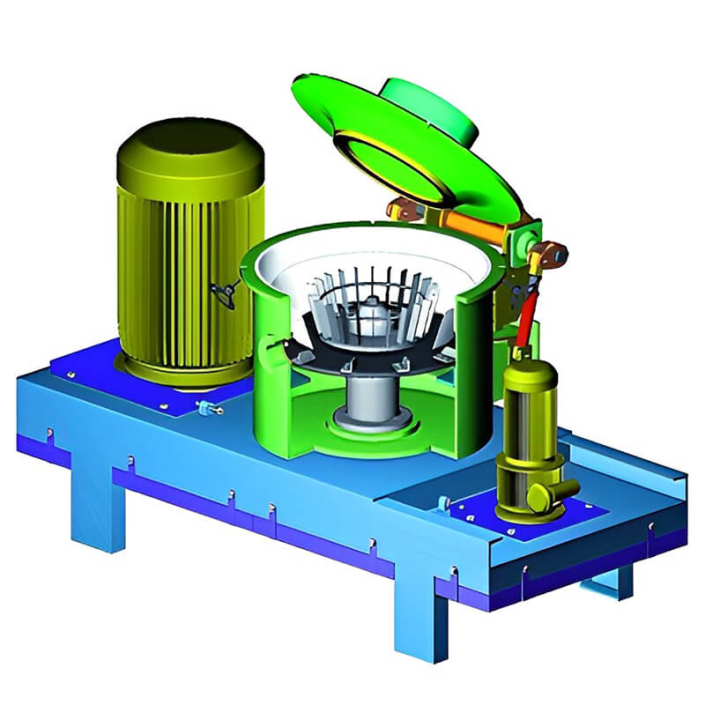

Air Classifier Mill

The air classifier mill combines a mechanical impact mill with an integrated dynamic air classifier. It is an air swept mechanical impact mill designed to grind materials down to 10 microns.

The air classifier mill uses air to carry the product through the fine grinding milling machine and classifying process. The feed material is conveyed through the pneumatic feed duct into the grinding zone. The main airflow enters the mill through the main air inlet underneath the grinding disc which rotates with tip speeds of 70 to 120 m/s. The grinding fineness is adjusted by the speed of the classifier wheel. Product of the desired particle size is drawn through the classifier, coarse material, is rejected for further size reduction. The fine particles are separated from the air in a cyclone / Filter downstream to the mill.

Features

- Typical particle size reduction down to 10 microns

- Controlled particle size distribution

- Grinding and classifying in one machine

- Temperature controlled grinding

- Easily accessible and changeable grinding media

- Minimizes material build up and food contamination

- Carbon steel or stainless steel construction available

Technical Data

Throughputs: 10 – 2000 kg/h

Grinding speeds: 60 – 130 m/s

Fineness: d97 10 – 400 μm

Hardness of material: 1 – 3 Mohs

Dust loads: 50 – 600 g/m3