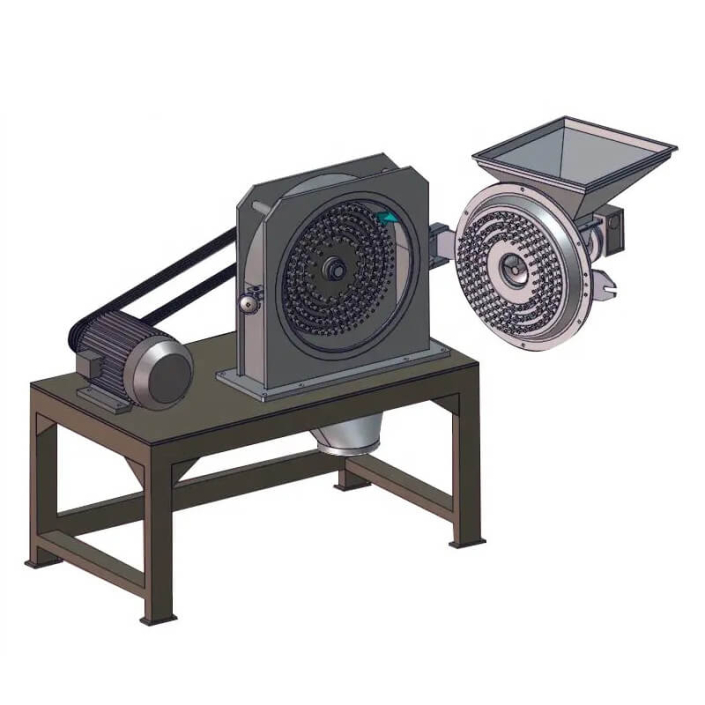

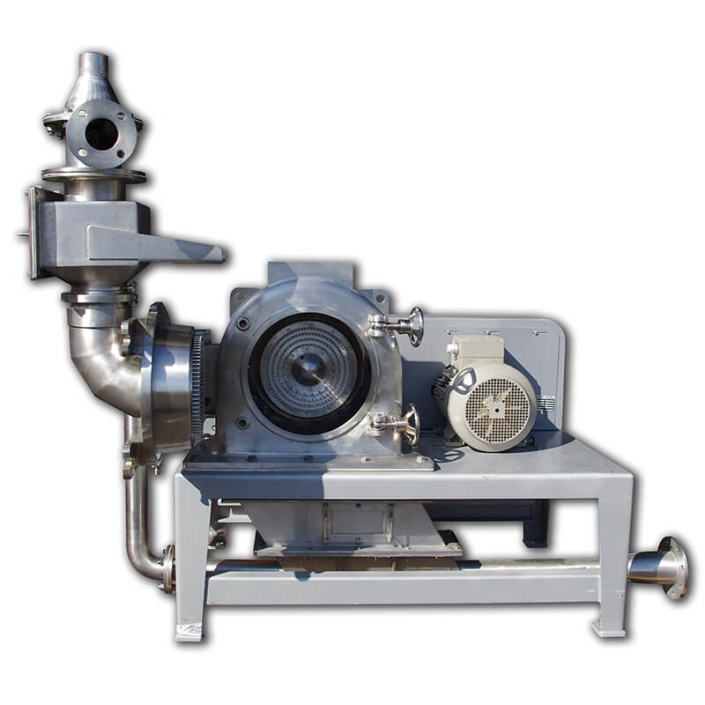

Pin mill

The impact pin mill provides coarse to fine grinding of crystal and brittle materials. The milling chamber consists of an outer stationary disc containing circular rows of pins that alternate with concentric rows of pins on the inner rotating disc. As metered material is gravity fed through the centrally located inlet of the stator disc, centrifugal force created by the high speed runner disc accelerates material causing particles to alternately impact the stationary pins and rotating pins before reaching the outlet.

The output fineness can be changed by replacement of the filtering-screen and adjustment of the rotor speed. With a wild range of applications to a variety of products, and the features of optional grind disc replacement for proper materials.

Features

- High powder fineness values in the range of approx.20-500µm

- Robust casing made of welded steel or stainless steel

- Precision machined housing and discs

- Vertical orientation of mill housing offers easier cleaning

- Durable components are easy to replace and clean

- Very wide application for different materials