Jet Mill

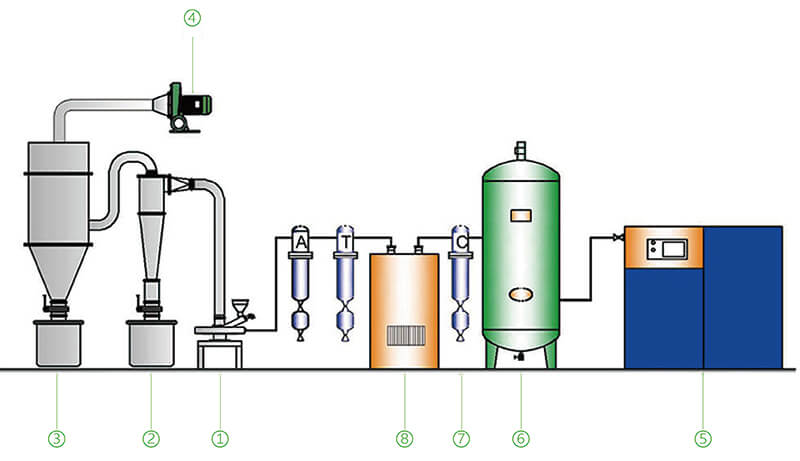

A jet mill is a grinding equipment used in super fine particle size reduction. It employs compressed air, gas, or steam to grind materials to a very fine consistency, often micron or even sub-micron level.

In a jet mill, particles are introduced into a high-speed stream of gas inside a grinding chamber. The kinetic energy in the stream of gas causes interparticle collision, and as the high-velocity particles hit against each other, they break apart, creating finer particles. This process of particle size reduction is known as micronization.

Jet mill pulverization is a technology that can grind powder to micron or even nanometer particles, which plays an extremely important role in many fields.